Custom bocad – your solution for customised CAD functionalities

Optimise your work processes with customised add-ins for bocad – available worldwide

Why Custom bocad?

With over 25 years of experience and as a member of the ‘bocad partner developer network’, Buhren Consulting offers solutions that are perfectly tailored to your requirements.

- Clear advantages

- Time savings through automated processes

- Error reduction through customisation

- New application possibilities for bocad in previously untapped areas

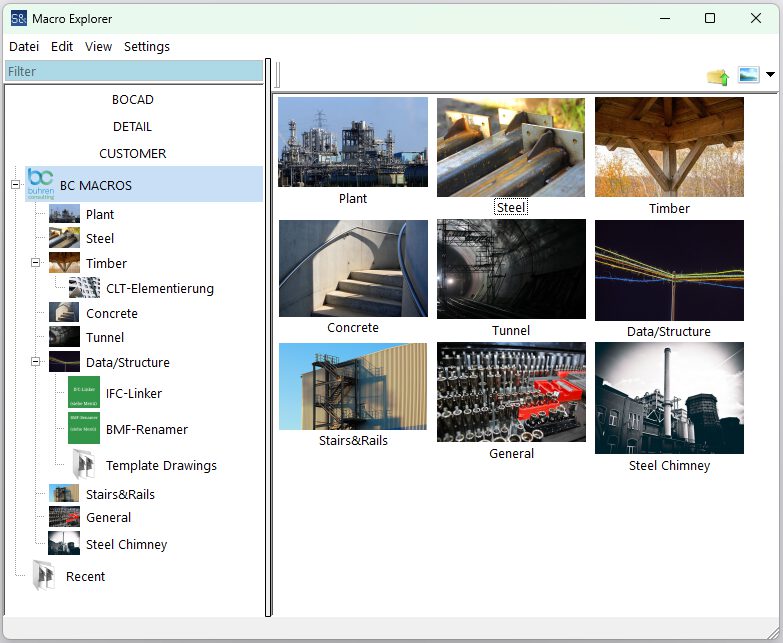

How does Custom bocad work?

1. Analysis of your requirements

2. Development of customised add-ins

3. Implementation, training and support

What is possible with Custom bocad?

Custom bocad offers you maximum flexibility.

Our goal: to optimally integrate your specific requirements into your bocad solution.

Possibilities with Custom bocad

Custom bocad allows you to use bocad on a completely individualised level. It combines the bocad standard functionalities and the personal requirements of your trade.

Here are a few examples of use:

- Plant steel construction

- Industrial chimneys, steel chimneys

- Industrial scaffolding

- Solar roof module construction

- lift tower construction

- Replacement staircase construction

- Tunnelling

- Canopy construction

- System construction for halls, stages, industry

- High rack construction

- Greenhouse construction

- Wind power plants

- Crane systems and hoists and much more

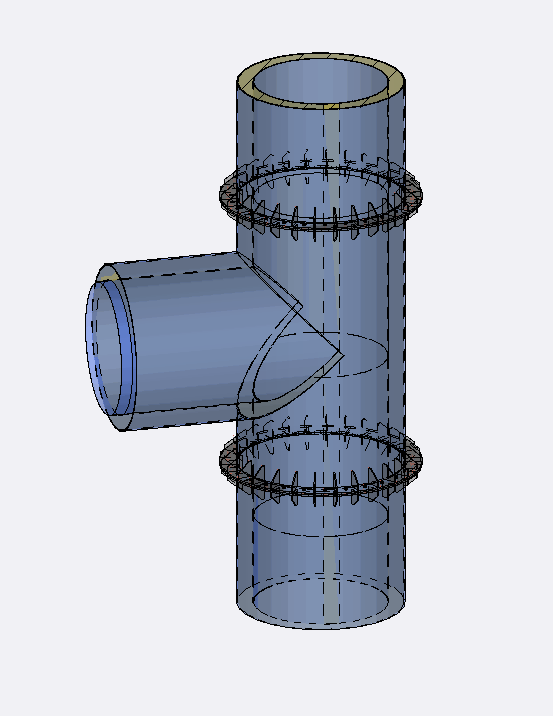

Creation of functions for generating special parameterised or fixed components and component groups that go beyond the elements available as standard.

On the one hand, this can be used for freely parameterised components. However, it becomes particularly interesting when the components are embedded in the logical context of your system.

Setting up functions for managing individual project and/or component-related data fields.

The data fields that are important to you for the further processing of data ‘after’ the CAD can already be recorded and managed in the CAD. This allows you to pass on any customised information to downstream systems, machines and people.

Automation of function sequences or modular structure of function groups.

This allows customised modules to be created that comprise specific function groups. This means that your specific design requirements can be implemented in a targeted manner and presented to the system users in a clearly structured way.

Creation of intelligent, parametric connections between components or component groups.

The developed connections are parametric and react independently to the user's input. This means that they are not rigid macros, but functions that react individually according to your specifications.

Set up system drawings for similar components or customise the drawing logic for freely designed components and component groups.

With these customised settings, you can ensure drawing output at the touch of a button. This also applies to the creation of parts lists and csv files.

Use of external data sources for parametric design, component types and much more, both read and write.

This makes it possible to tap into or use existing data sources in order to avoid duplicate data storage.

Creation of automated and customised interfaces, also bidirectional.

This opens all doors to allow your data in CAD to communicate with other systems in operation. It is also possible to address other software systems via an API (Application Programming Interface) so that the systems can communicate with each other directly and without an interface.

Tools that are also used outside the CAD system can be created to optimise processes.

These special tools can be used to automate internal, recurring and error-prone workflows so that they run safely and reliably.

In the course of customisation, the user interface is adapted for the user so that the functions can be found and used quickly.

You will receive personalised advice and support throughout the entire implementation process. We work our way from rough to fine, making adjustments from time to time during operation if necessary.

From the very first meeting, address any open issues that concern you, where you see potential for optimisation or where you suspect there are hurdles.

All developments and customisations are embedded in your bocad installation and interact with the functionalities already existing in bocad.

This allows you to utilise the full strength and range of bocad without restriction.

Here are a few highlights as a first impression:

- Over 40 years of continuous development on our own database

- Worldwide established system in professional use

- 3D design of standardised components and special components

- Open material library

- Huge library of steel parts, timber components, roof & wall profiles and much more

- Use of existing design macros

- Creation of structures and substructures

- Intelligent 3D library for your own component libraries

- Bolted, welded and neutral connections as standard

- System adapts to the user (presetting sets)

- Numerous installation, collision and fastener checks

- Possibility of using system components/standard components

- Automatic identical part recognition and item number assignment

- Automated drawing derivation

- Automated list derivation

- Numerous export/import functionalities

- Highly open, adaptable and expandable system (customisation)

- Integration of point clouds into the model

![[:de]Buhren Consulting[:]](https://buhren-consulting.com/wp-content/uploads/2019/09/cropped-horizontal_print-1-1.png)